LAYUP ARCHITECTURE

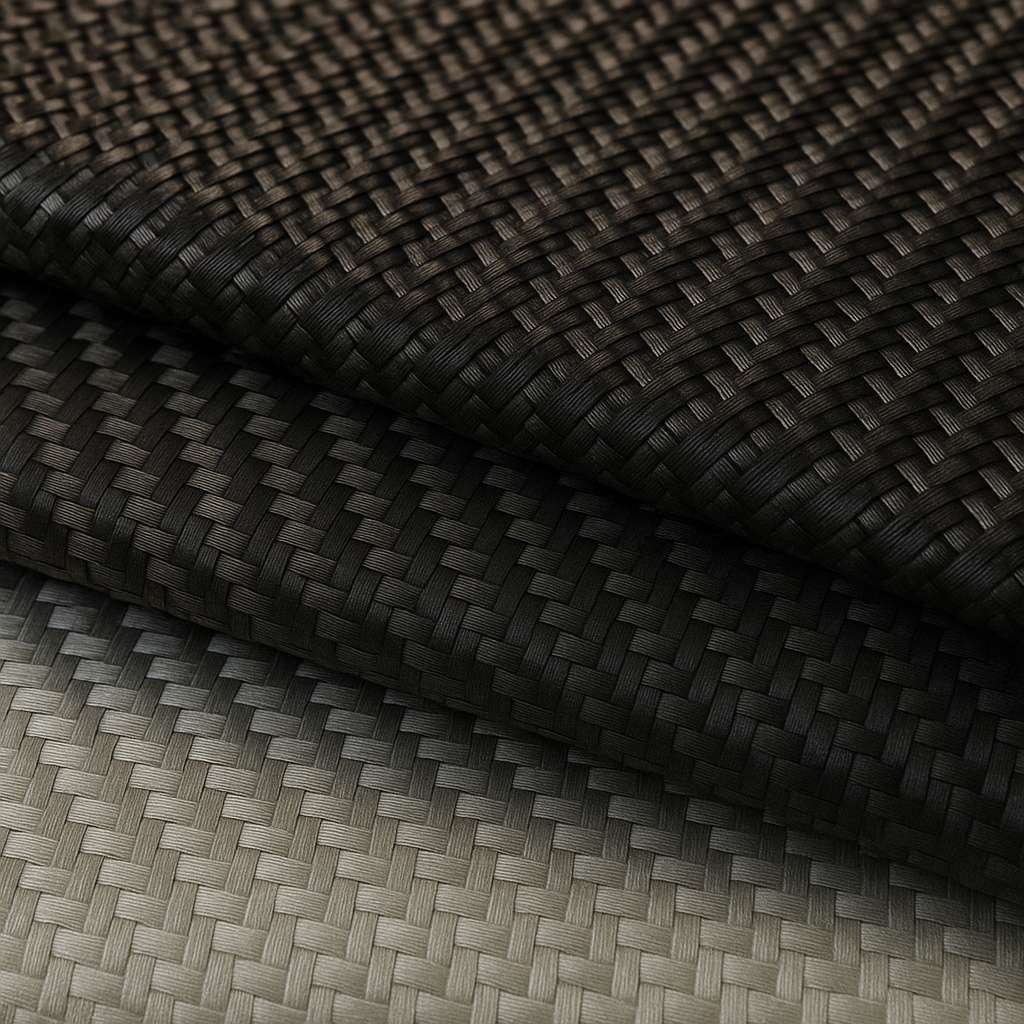

Fibreglass liner, 11 structural carbon plies and an external sleeve tuned for hoop and axial loads.

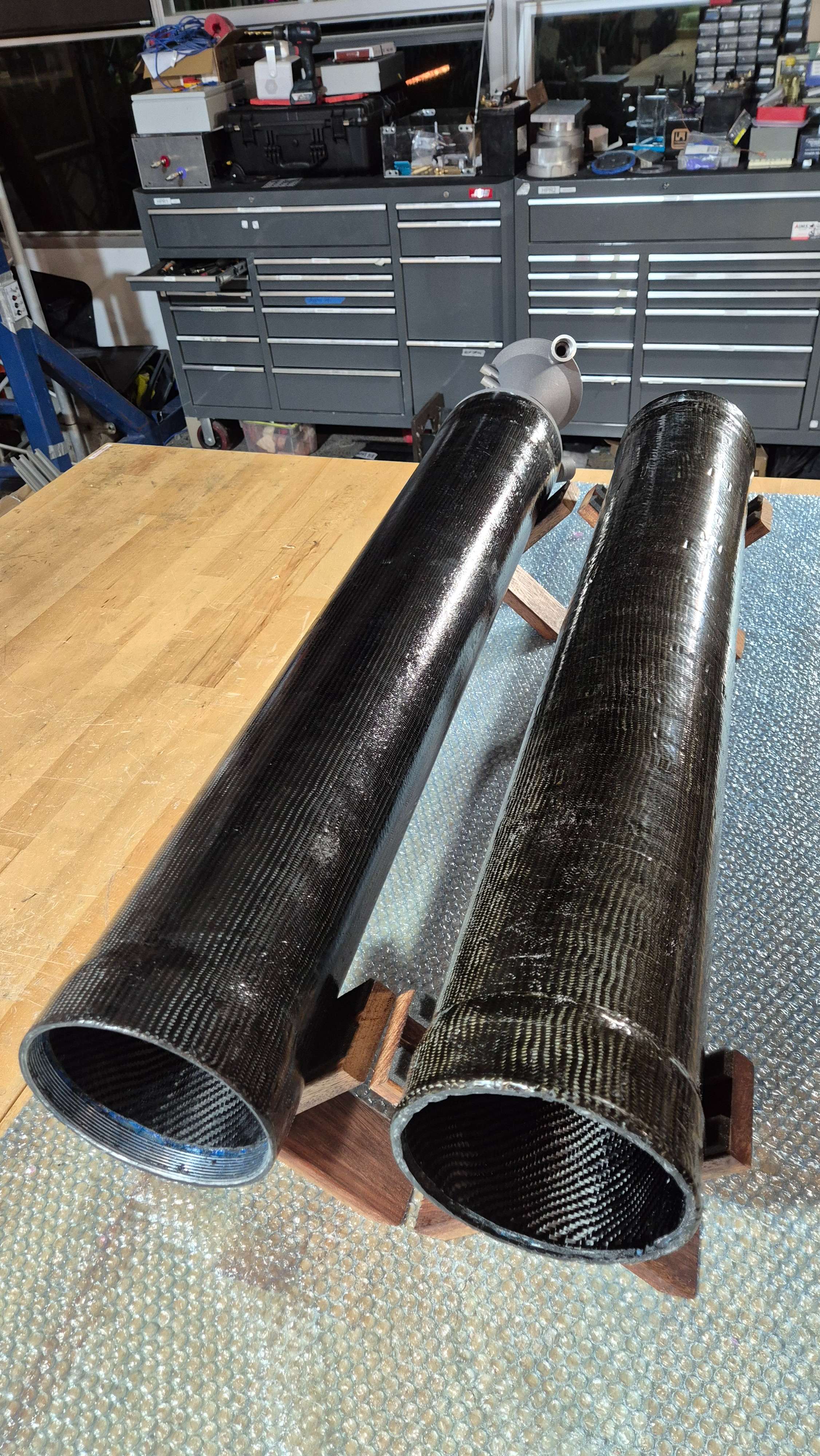

Solaris MkIII Type-V COPV Hybrid Rocket Combustion Chamber

As Propulsion Engineer on Solaris MkIII, I was responsible for the design and optimisation of a composite combustion chamber wall. After trading conventional aluminium, Type-II COPV concepts and full Type-V COPVs, I led the development of the first all-composite combustion chamber ever attempted by the team.

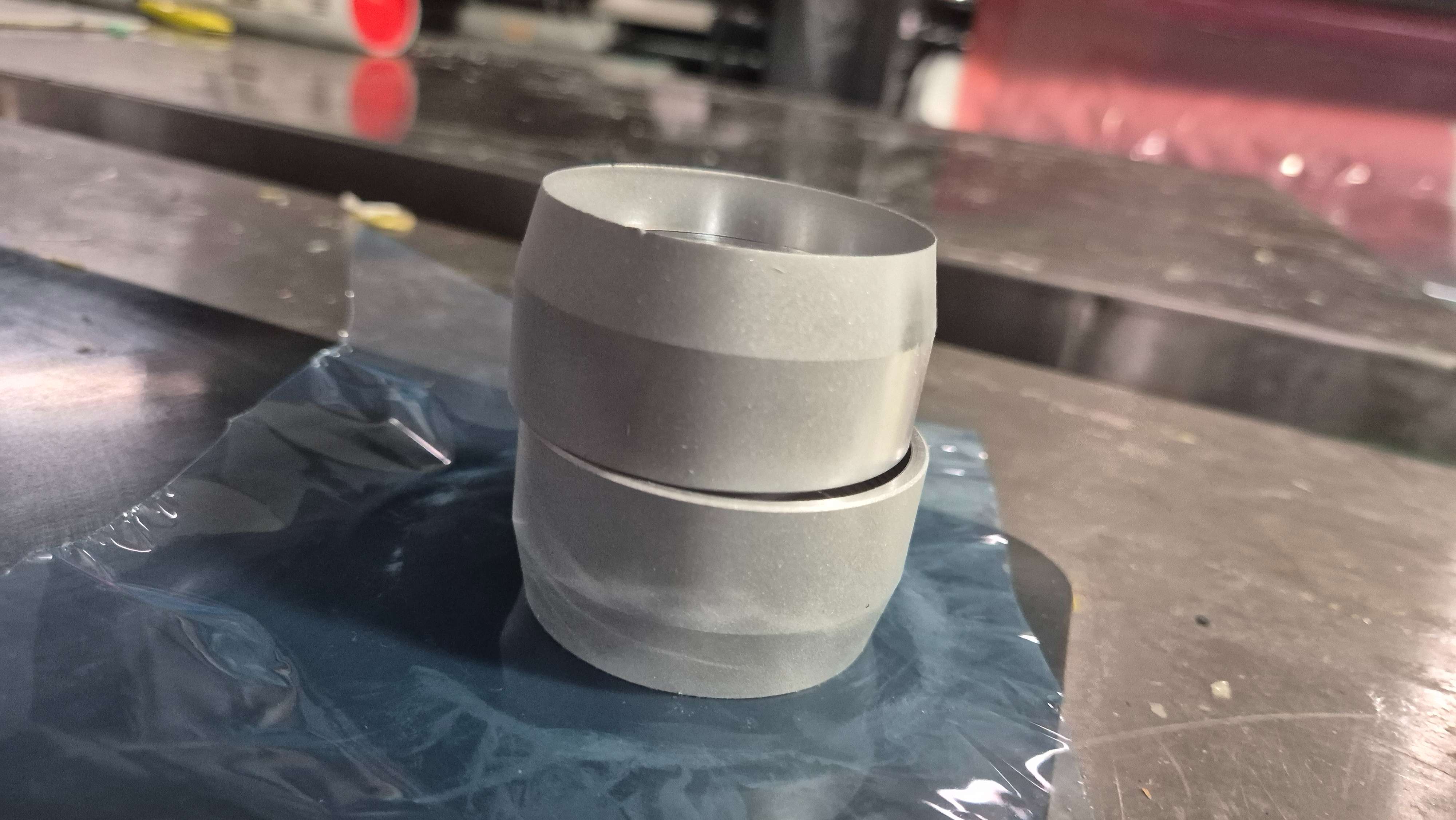

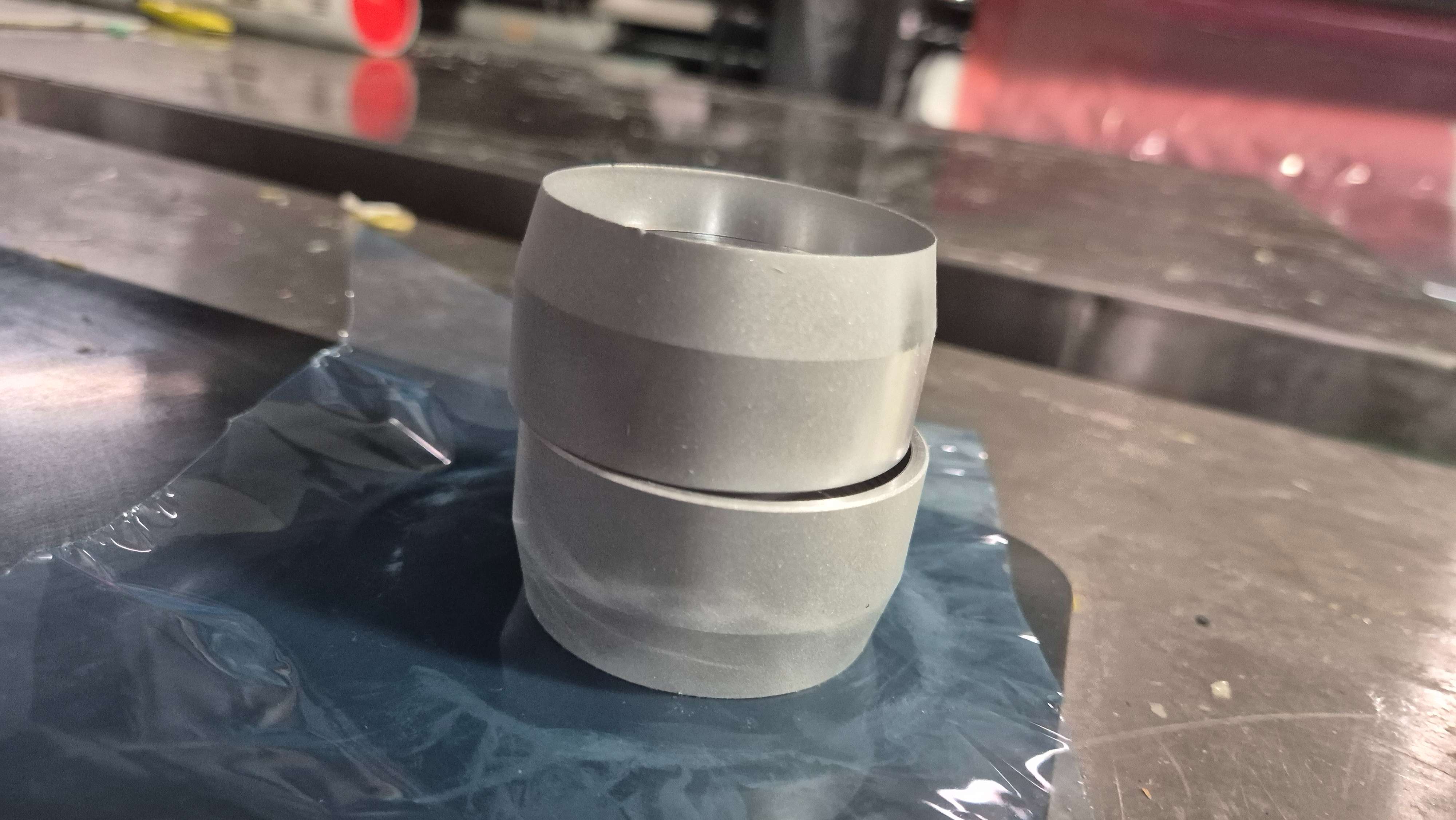

The final design is a Type-V Composite Overwrapped Pressure Vessel (COPV) that replaces a thick-walled aluminium chamber with a fibreglass-lined, carbon-fibre overwrapped shell and Al7075-T6 threaded couplers. This architecture reduces chamber wall mass by more than 60% relative to an equivalent aluminium design while maintaining a structural Factor of Safety > 3 at the expected chamber pressure.

The wall structure is a multi-material laminate designed for hoop strength, thermal isolation, and manufacturability using university workshop tooling, composites workshop and the teams accsess to composite materials. The baseline layup is:

Fibreglass liner, 11 structural carbon plies and an external sleeve tuned for hoop and axial loads.

Al7075-T6 couplers bonded into the laminate transfer load to the injector and nozzle.

Internal fiber glass heat protective layer

the chamber is constructed as one monolithic piece to maximise composite stregnth with bonded couplers at each end to interface with the injector and nozzle. The internal fibreglass layer acts as a thermal barrier and sacriffical layer to prevent the high combustion temperatures from degrading the carbon fibre resin matrix. while the external sleeve protects against handling damage during assembly and transport.

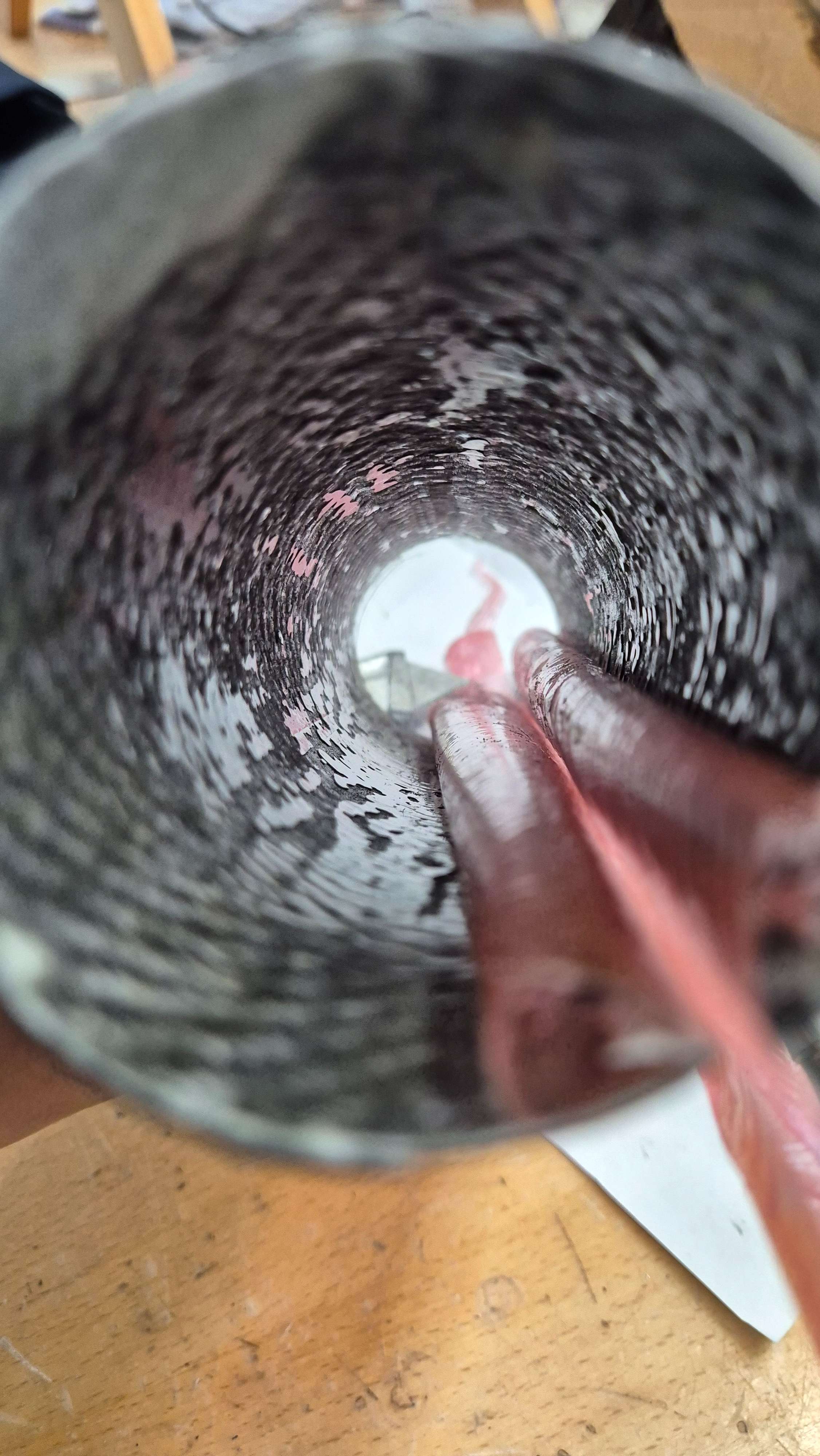

Developing a repeatable manufacturing method for a Type-V combustion chamber required several iterations. I progressed through four main prototype approaches, starting with simple heatshrink-only consolidation and evolving towards a full vacuum-bagged, heat-treated process using Technirez R2600 / H2409 high-temperature resin.

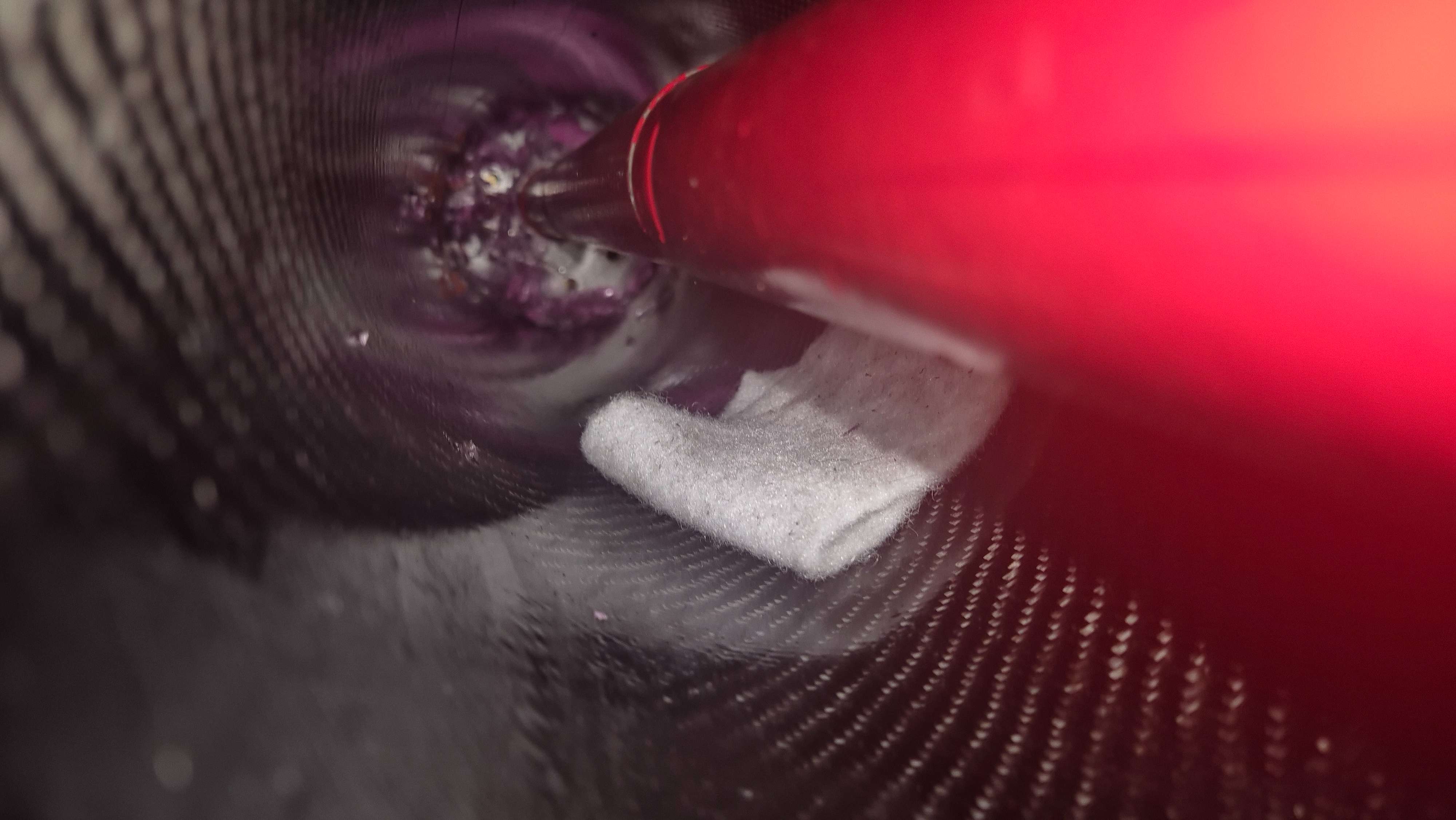

Early tubes used a fibreglass wet layup with heatshrink consolidation, which caused fibre wrinkling and resin pooling. Doughnut-style vacuum bagging improved cosmetic finish but produced soft, leaking laminates. Through later attempts I converged on a hybrid process: vacuum-bagged fibreglass liner, carbon fibre overwrap, and controlled heatshrink compression.

This informed the final large-scale workflow involving proper mandrel prep, Resin Pre-Coat (RPC) bonding of aluminium couplers, a staged composite layup, and a multi-step thermal cure out to 200 °C.

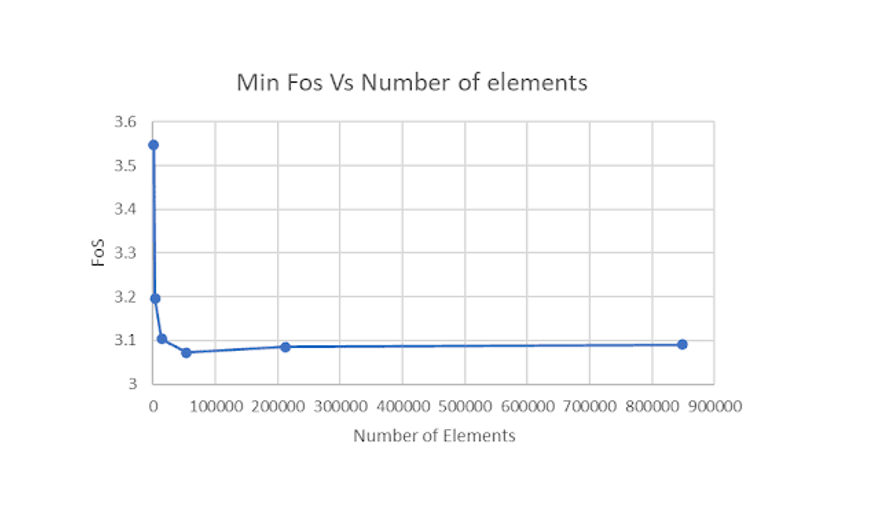

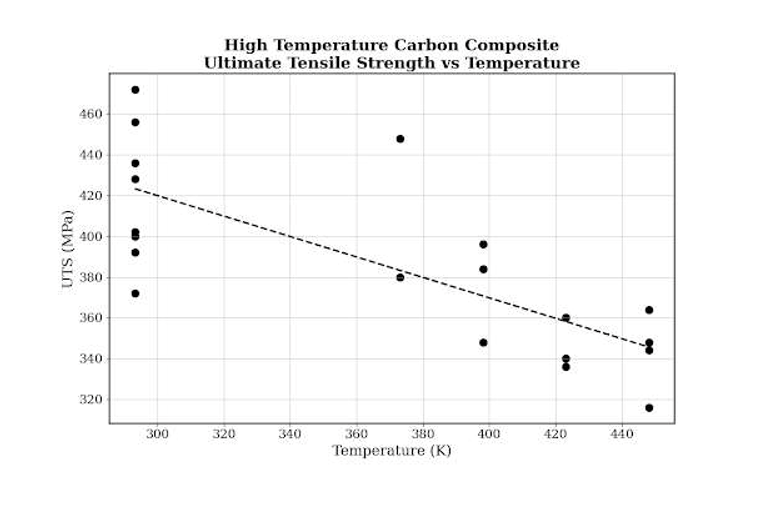

The chamber wall was analysed using ANSYS (ACP + Static Structural). Ply-level orthotropic modelling confirmed that the laminate maintains a Factor of Safety above 3 at peak operating pressure. Interface stresses at the couplers were examined to ensure the preferred failure mode is thread shear rather than COPV rupture.

Sub-scale burst tests closely matched simulation predictions and validated the manufacturing approach, shrink-tape consolidation, and R2600 resin cure schedule. Full-scale proof testing will confirm the chamber is leak-tight and structurally sound to 1.5× MEOP, this is currently in progress.

A full validation program was completed, including:

Flat laminate coupons characterised the strength and stiffness of the CF and FG systems.

60 mm COPVs were hydro-tested to burst to validate analytical sizing and FEA.

The assembled chamber will be taken to 1.5× MEOP to confirm leak-tightness and margin.

The Solaris MkIII composite combustion chamber represents a significant advance in the team's

capability. The Type-V COPV architecture delivers high structural performance with minimal

mass, while the manufacturing workflow developed for this project forms the basis for future

high-pressure propulsion hardware.

This was a huge learning experience for me as a propulsion engineer, getting to grips with composite design, manufacturing and testing.

Leading the development of the first all-composite combustion chamber for the team was a challenging but rewarding experience,

and I am proud of the final result which I believe will set a new standard for student rocketry projects.

Some key takeways from this project were the importance of iterative prototyping and testing to refine manufacturing processes, as well as the need to balance theoretical design with practical considerations like manufacturability and assembly. But most importantly, the importance of properly machining parts and hitting critical tolerances. unfurtunatly due to time constraints we were unable to machine the couplers to the required tolerances which led to some issues during assembly and a rapid unscheduled disassembly after proof testing at the Airborne test site Overall, this project has significantly expanded my skills and knowledge in propulsion engineering and composite materials.