Composite Overwrapped Combustion Chamber

Type V COPV combustion chamber for Solaris MkIII, designed for 60 bar operation, combining composite overwrap with metallic couplers and extensive FEA validation.

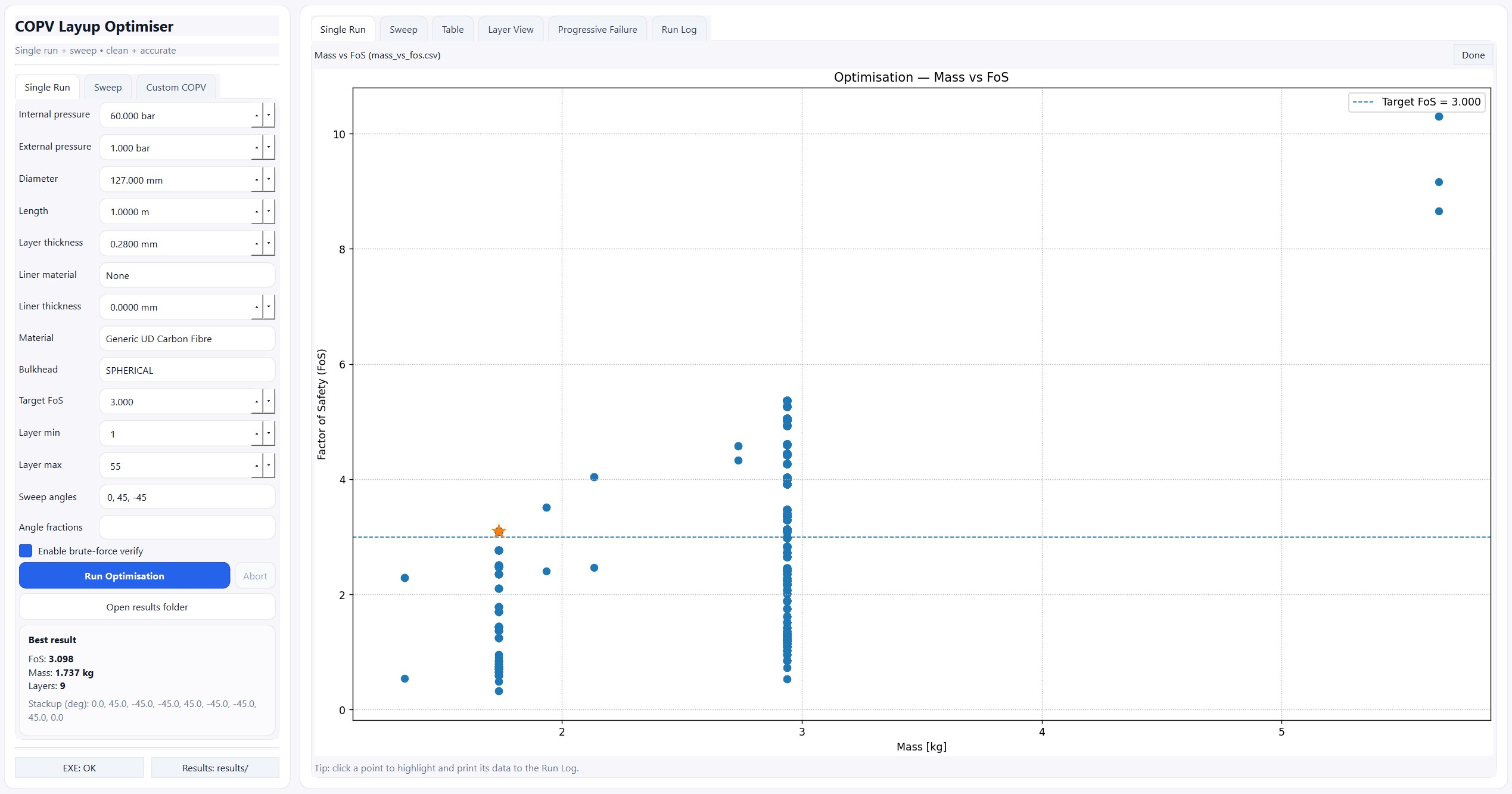

COPV layup Optimization

Profestional standard code design for optimizing the stackups for a composite vessel. featuering a modern python GUI and rapid C++ backend processing.

Regeneratively Cooled Nozzle

Ethanol-cooled hybrid rocket nozzle concept, using RPA and MATLAB to size cooling channels and assess wall temperatures and pressure drops.

Toothless

Early experimental build exploring CAD, FEA and hands-on fabrication, forming the base for later composite and propulsion work.

PDT Coffee Table

CNC-routed plywood table designed as a furniture/manufacturing exercise in tolerances, fixturing and post-processing.

PDT Work Bench

Heavy-duty bench project for workshop organisation, focused on joinery, stiffness, and workflow layout.