FAMILY LIVING ROOM

Designed for a busy family space where sport, movies and entertaining are part of daily life.

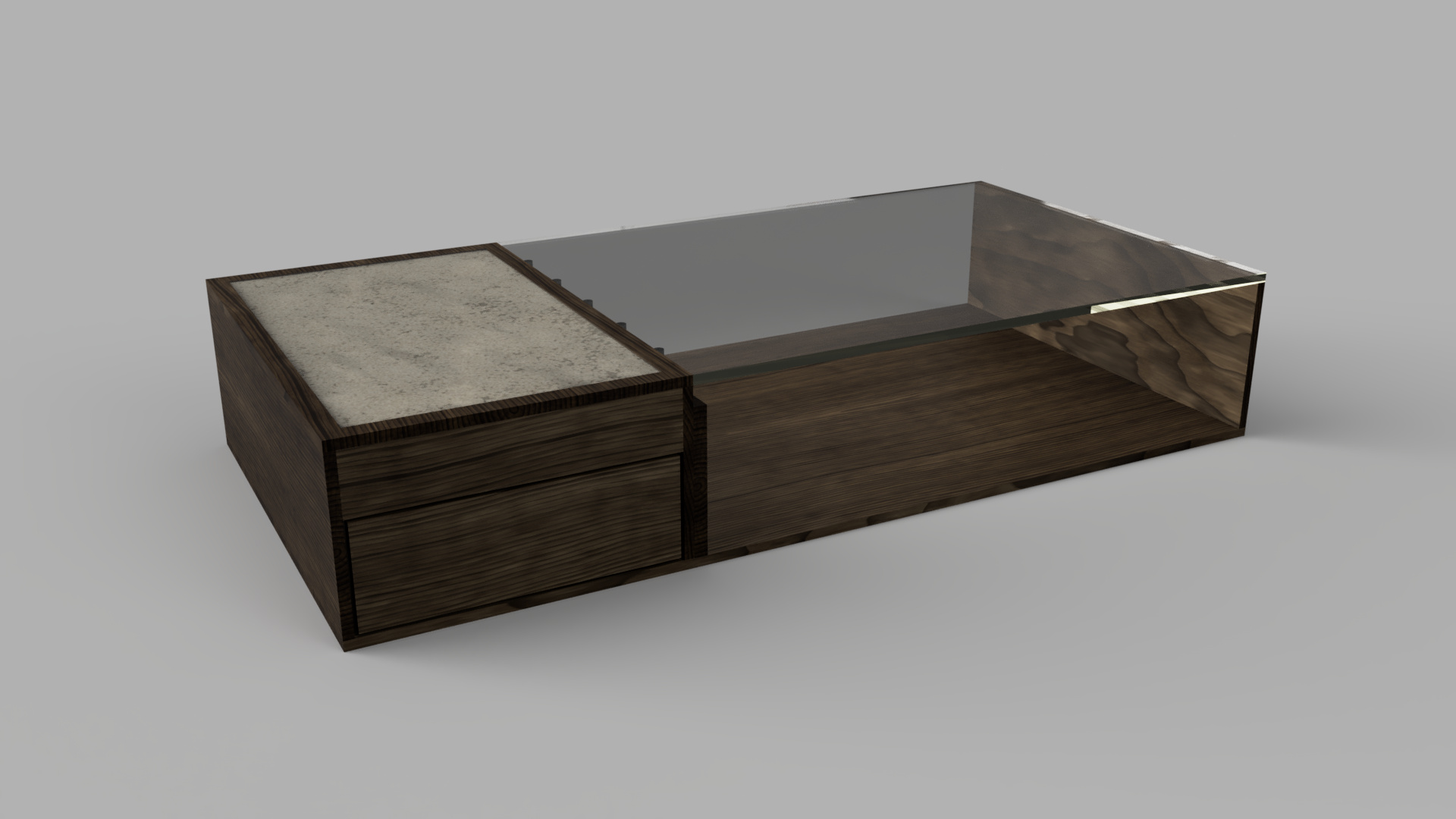

PDT major project – a walnut, steel and acrylic centrepiece with a CNC-driven kinetic sand sculptor.

This coffee table was designed as a centrepiece for a family moving into a new home in Highton. They wanted a functional table that fits a modern, minimalist interior but also has a feature that immediately draws attention when you walk into the room.

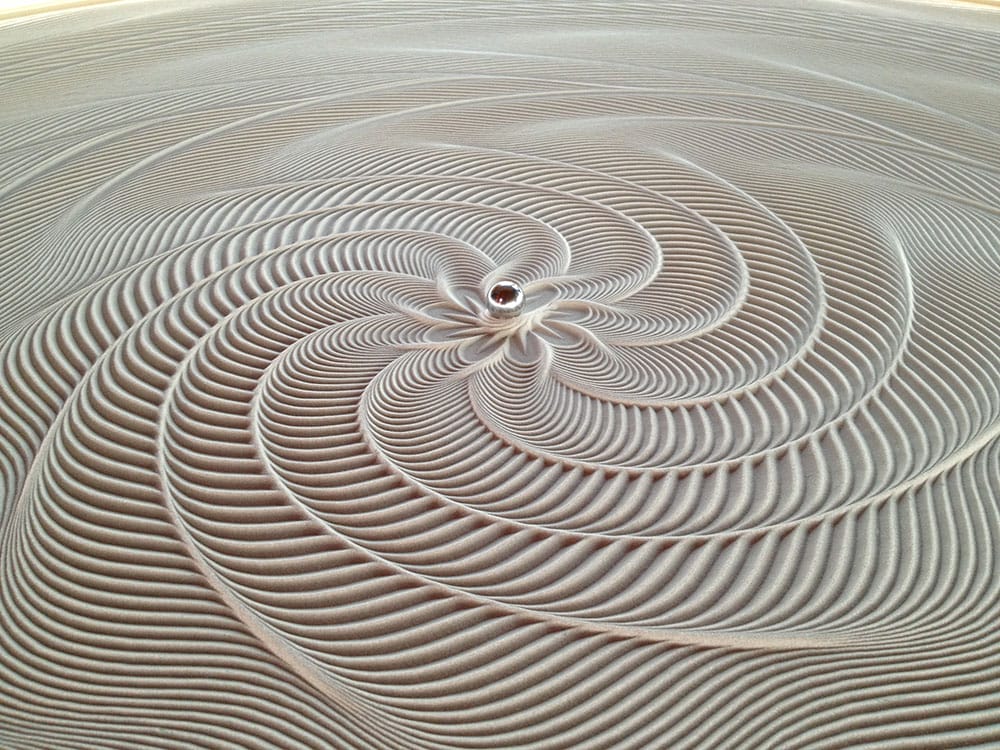

The result is a kinetic sand coffee table: a low, rectangular table with storage drawers, a walnut top and a CNC-driven metal ball that traces patterns through sand beneath a clear acrylic cover. The table balances durability, ergonomics and everyday usability with a visually engaging interactive feature.

Early design exploration compared multiple layouts for the sand tray, storage, frame height and overall proportions. These iterations helped dial in the balance between visual impact and everyday usability. the following images show some of the designs:

The end users are a family of four plus grandfather, with a strong interest in sport, entertaining and modern interior design. They prefer light walls, strong contrast, smooth finishes and high quality, durable furniture that can handle everyday use and frequent gatherings.

The brief was to produce a coffee table that:

Designed for a busy family space where sport, movies and entertaining are part of daily life.

Contemporary, minimalist and bohemian references – timber contrasted with black steel.

The table is a low, rectangular form with a solid timber top that visually “floats” inside a black powder-coated steel frame. The central section of the top is dedicated to the kinetic sand sculptor: a shallow tray filled with fine sand, covered by a flush acrylic panel so the surface remains usable as a normal coffee table.

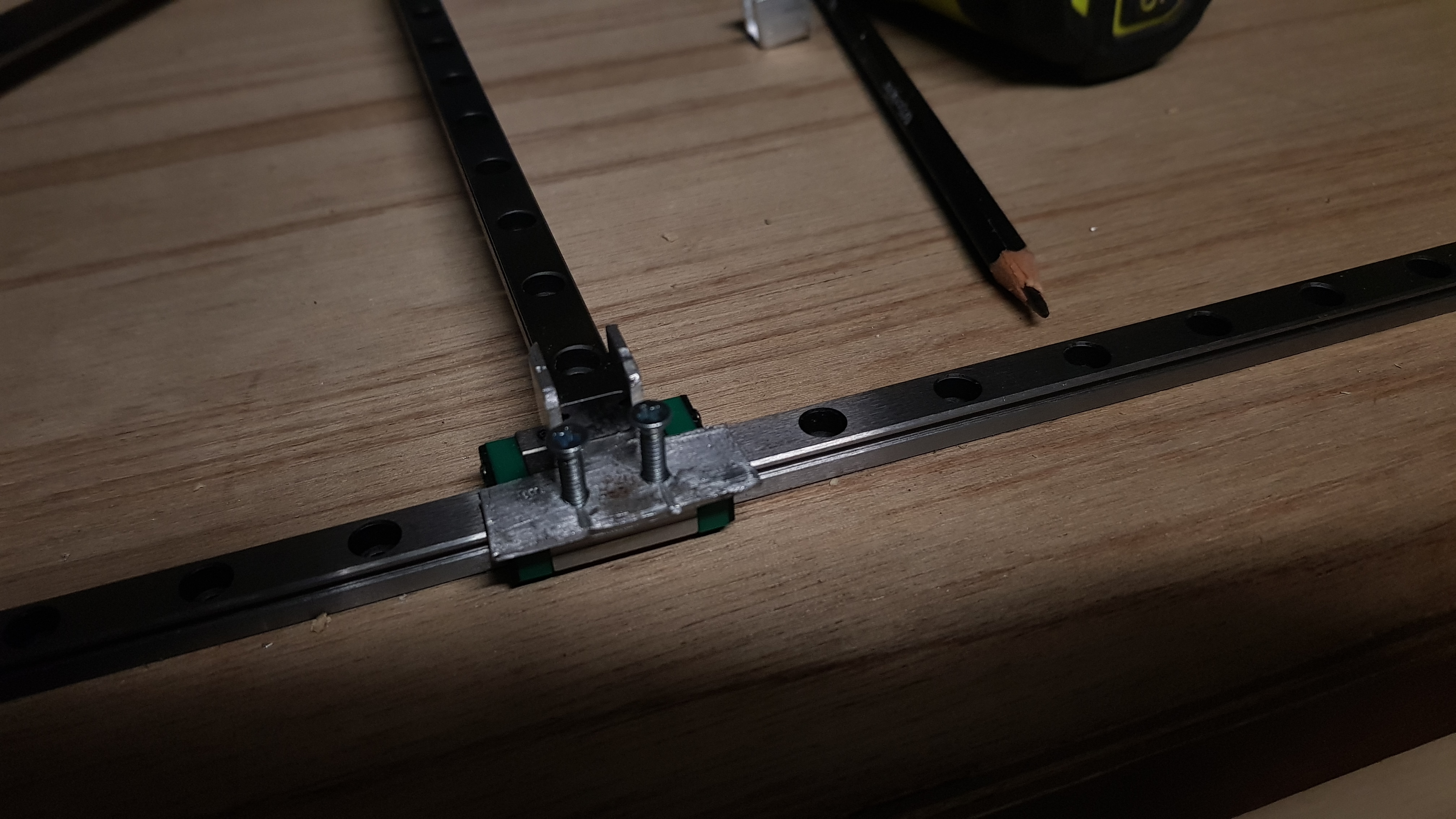

Underneath the sand tray, a Cartesian gantry moves a powerful magnet in X and Y. On the sand surface, a steel ball follows the magnet, carving smooth parametric paths that slowly erase and redraw patterns over time. Paths are stored as CNC-style toolpaths and driven by stepper motors under microcontroller control.

The structure combines engineered timber cabinetry with a welded steel frame. Walnut was chosen for the visible timber due to its rich grain, durability and premium feel, contrasted against a satin black powder-coated steel base. The sand tray is sealed with a bent acrylic cover that improves safety compared with glass while keeping the feature clearly visible.

Joinery uses dominoes and careful glue-ups to keep faces clean and free of visible fasteners. Twin soft-close drawers are integrated into the lower timber volume to provide hidden storage for remotes, controllers and other living-room clutter.

Samples of timber, steel finishes, acrylic thicknesses and different sand types were tested to balance durability, appearance and ease of cleaning. The subjective best choices were used in the construction of the table, ensuring the end-users needs were met and the final product was up to their liking.

Shown above are some of the diffrent materials that we're tested, such as American Black Walnut, steel with a black powder coating, and a clear acrylic sheet for the kinetic scuplture cover.

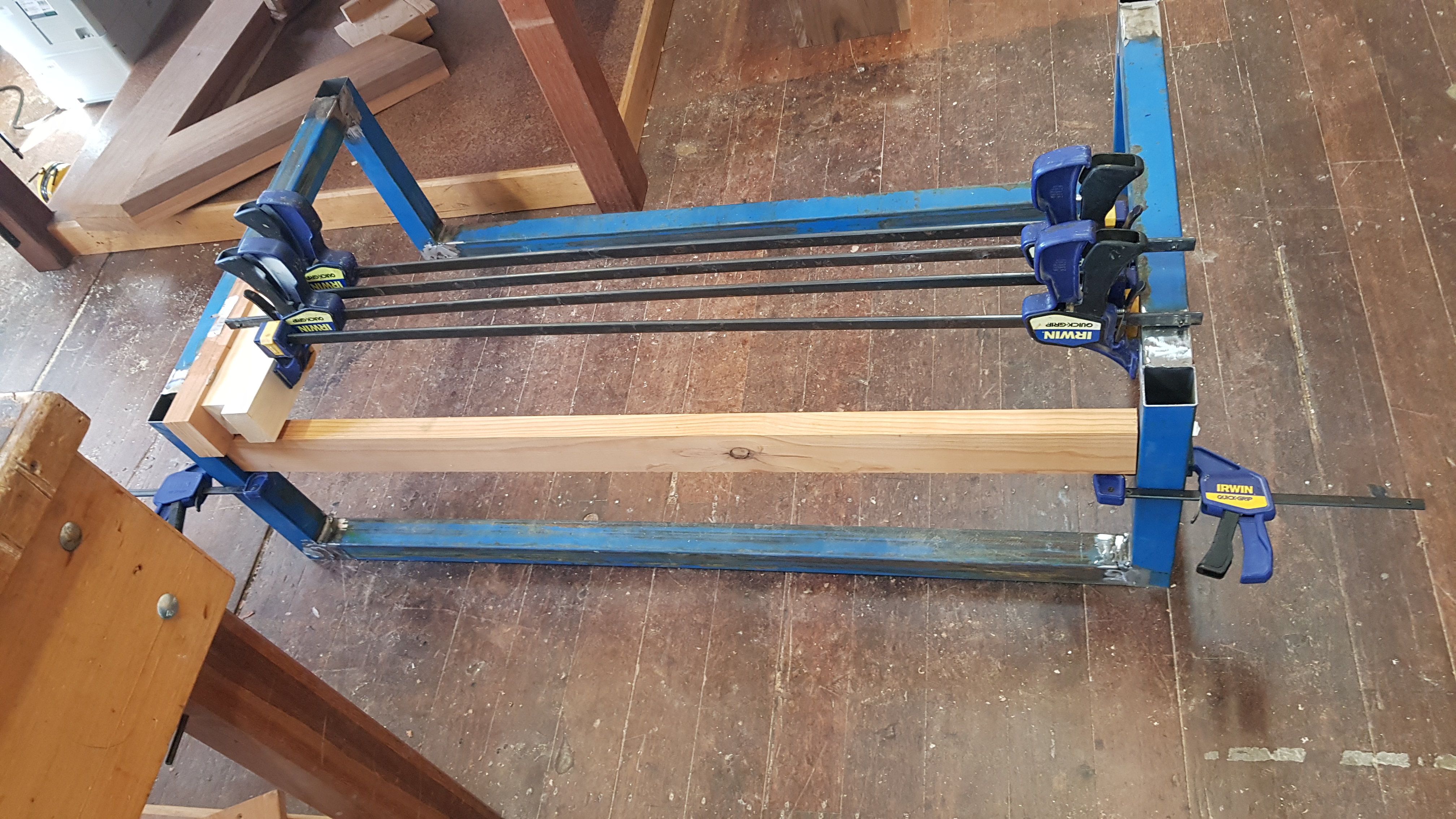

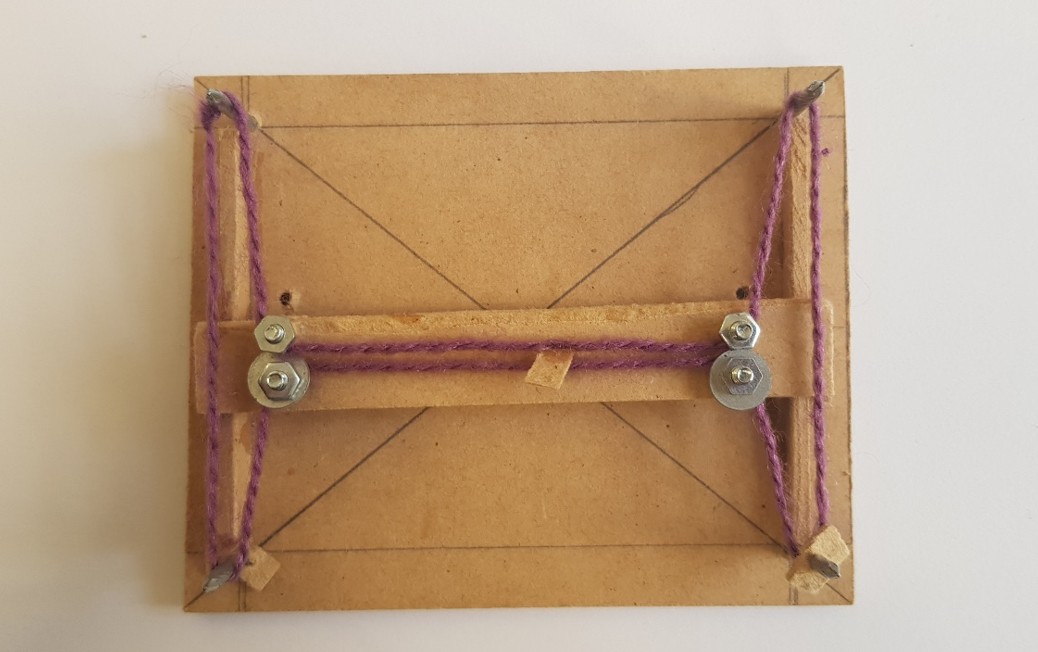

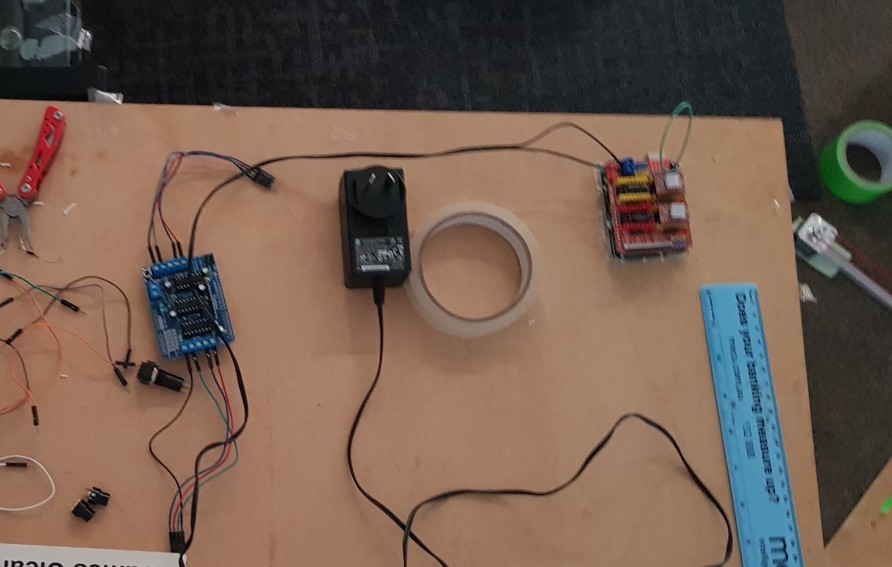

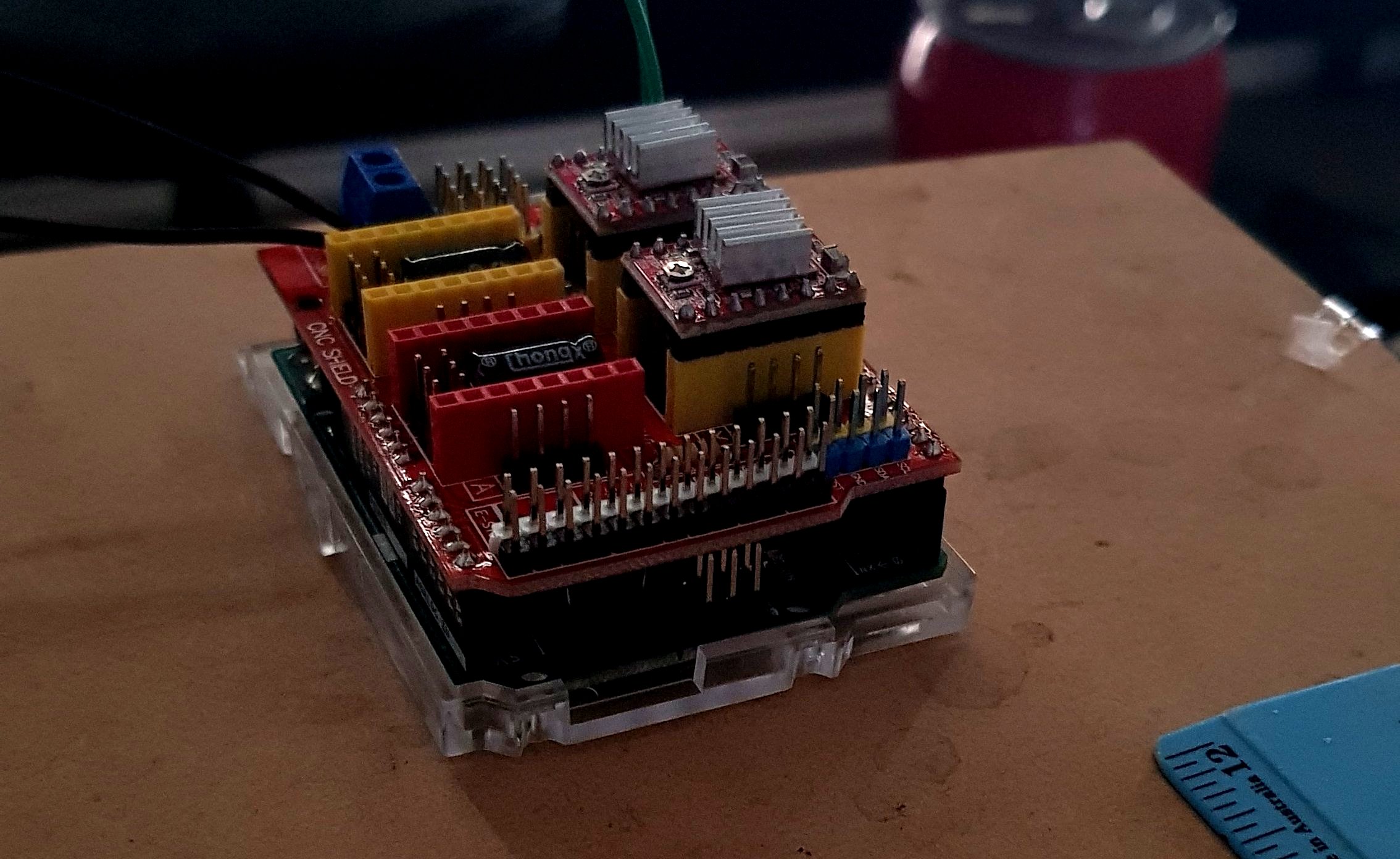

The motion system is built around stepper motors, belt-driven linear rails and an Arduino-based GRBL controller. A small computer stores pattern files and streams G-code to the controller, which handles homing, coordinated motion and speed control. Early prototypes used high-friction aluminium tracks before moving to proper linear rails for smoother, more reliable motion.

LED lighting around the sand tray is controlled via a secondary microcontroller, allowing colour changes and subtle animations that emphasise the moving sand pattern without overpowering the room.

NEMA steppers, belt-driven linear rails, end-stops and a compact gantry sized to the table footprint.

GRBL-based motion controller with separate LED driver, powered via concealed supply in the frame.

The table was checked against a detailed evaluation matrix covering size, durability, stability, aesthetics, ergonomics and sustainability. Physical testing included spill tests on the top, sanding and finishing trials, weld practice coupons, and full motion tests of the CNC system to remove stiffness and jamming issues.

The final design scored highest of five options in the evaluation ranking and met the end users’ expectations for both day-to-day function and standout visual impact in the room.

The build required coordinated welding, timber work, sanding, finishing and careful assembly of the motion system and electronics before final installation.

The finished kinetic sand coffee table combines furniture design, CNC motion control and product development into a single piece of functional furniture. It works as a robust, easy-to-clean coffee table with storage, while the kinetic sand sculptor and lighting transform it into a living centrepiece when powered on.

Building the piece developed my skills across user research, CAD, working drawings, welding, advanced timber joinery, electronics integration and scheduling a complex production plan from raw stock through to installation in the client’s home.