Quality Statement

Quality was explicitly defined in the folio: the bench must be ergonomic for extended use, have rounded corners and a fully sanded finish, and be manufactured to ±5 mm dimensional tolerance with correctly fitted, strong joints.

Year 11 Product Design — full folio → concept selection → build → evaluation

This project started with a real problem in a home garage workshop: tools and equipment were stored on the floor, there was no dedicated workspace, and no organised storage for day-to-day making and repairs. The solution was a purpose-built workbench designed to be strong, portable, and long-lasting — with an emphasis on clean aesthetics and workshop practicality.

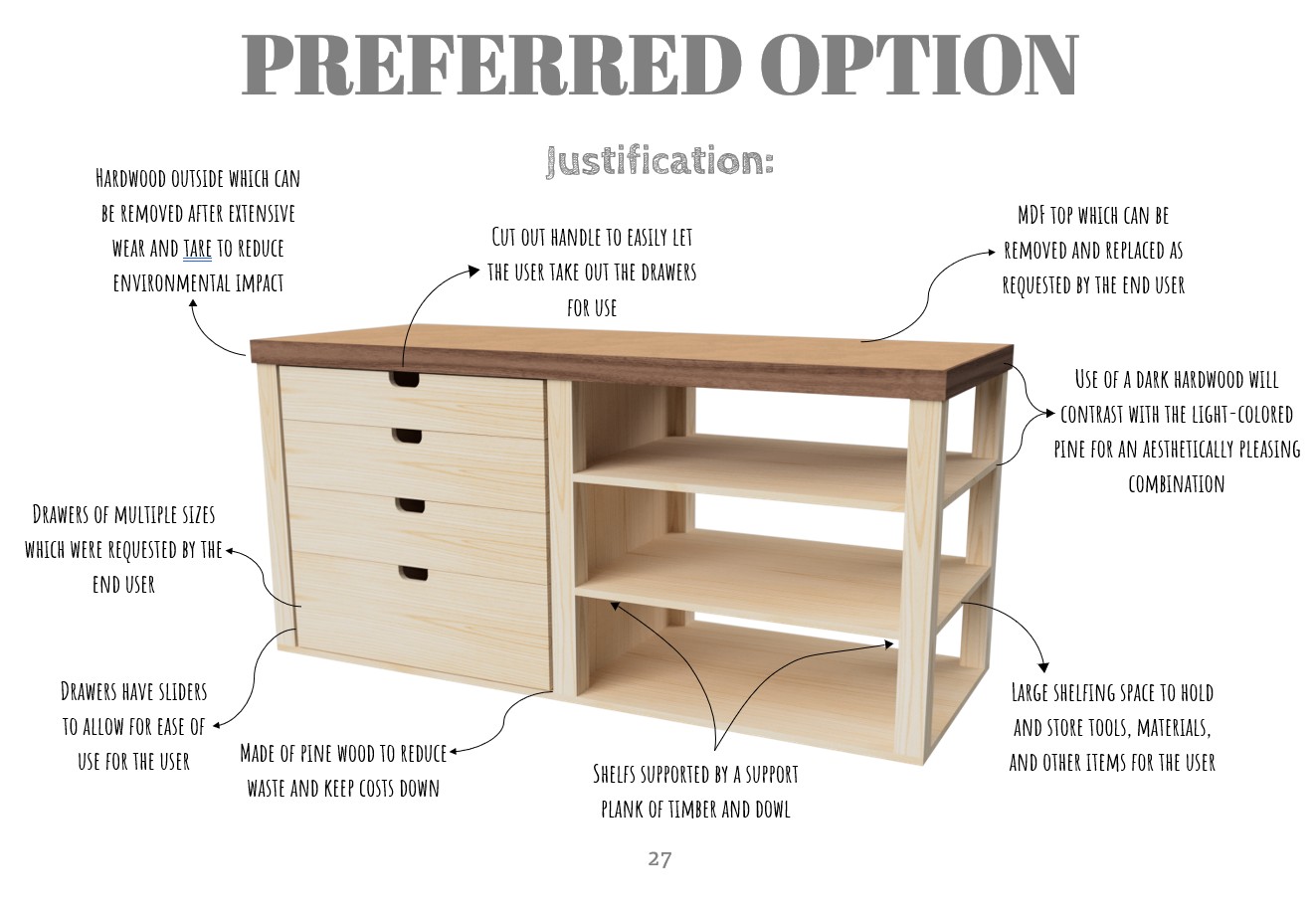

The final design combines a large work surface, symmetrical shelving, and multiple drawer heights so small parts and bulky tools can be stored separately. A key feature is a replaceable top system: the bench is built to take real abuse, but the wear surfaces are designed to be swapped when damaged.

View Workbench Folio (PDF) DownloadThe end user was defined as a 16-year-old student who enjoys building items out of wood and other materials. He works casually (café + cleaning), has a stable income for a student, and spends a lot of time creating projects — but his garage environment had no proper work zone or storage system.

The main pain points were:

To solve this, the bench was designed with extra support members to reduce break points, wheels for mobility, and a replaceable tabletop system so damage doesn’t end the product’s life.

The project had clear dimensional targets to ensure the bench fit the garage and was comfortable to use:

Primary constraints:

Additional considerations were included to raise functionality and finish quality:

Primary function: a stable working surface for building, repairs, and general workshop tasks.

Secondary function: organised storage and protection for tools and equipment when not in use.

The design priority was durability: the bench must resist sudden impacts (hammer strikes, dropped tools, general workshop abuse) and remain safe and usable over extended periods.

Quality was explicitly defined in the folio: the bench must be ergonomic for extended use, have rounded corners and a fully sanded finish, and be manufactured to ±5 mm dimensional tolerance with correctly fitted, strong joints.

Three design options were evaluated using consistent criteria: sturdiness, portability, interchangeable tabletop, sustainability, and garage fit. Option 1 was selected as the preferred concept.

Evaluation scoring (Option 1):

The end-user rated Option 1 highest and described the design as clean, minimalistic, and aesthetically pleasing. He highlighted the shelving and varied drawer sizes as key requirements, and confirmed the garage fit and access constraints were satisfied.

The final product incorporates multiple functional upgrades and durability-focused details:

Production was planned using a materials cutting list and a sequenced process table including tools/equipment, safety precautions, and estimated time per step. This was used to control accuracy and reduce rework.

The cutting list covered major components including MDF top, pine legs, top supports, shelves, and drawer parts (fronts + internal pieces), ensuring the build could be completed inside budget.

| part | material | Length (mm) | Width (mm) | Hight (mm) | amount |

|---|---|---|---|---|---|

| MDF top | MDF | 1950 | 760 | 25 | 1 |

| Long top side | ... | 1970 | 10 | 65 | 2 |

| Short top side | ... | 780 | 10 | 65 | 2 |

| Legs | Pine | 850 | 70 | 70 | 6 |

| Top supports | Pine | 850 | 620 | 20 | 2 |

| Shelfs | Pine | 760 | 975 | 20 | 2 |

| Small drawer front | Pine | 850 | 20 | 150 | 2 |

| Medium drawer front | Pine | 850 | 20 | 190 | 4 |

| Large drawer front | Pine | 850 | 20 | 270 | 4 |

| Small drawer large piece | Pine | 820 | 20 | 150 | 4 |

| Small drawer small piece | Pine | 330 | 20 | 150 | 4 |

| Medium drawer large piece | Pine | 820 | 20 | 190 | 8 |

| Medium drawer small piece | Pine | 330 | 20 | 190 | 8 |

| Large drawer large piece | Pine | 820 | 20 | 270 | 4 |

| Large drawer small piece | Pine | 330 | 20 | 270 | 4 |

The sequence plan included the full workflow: measuring and marking, cutting, domino joinery, glue-up/clamping, sanding, assembly, routing, and final drawer runner installation.

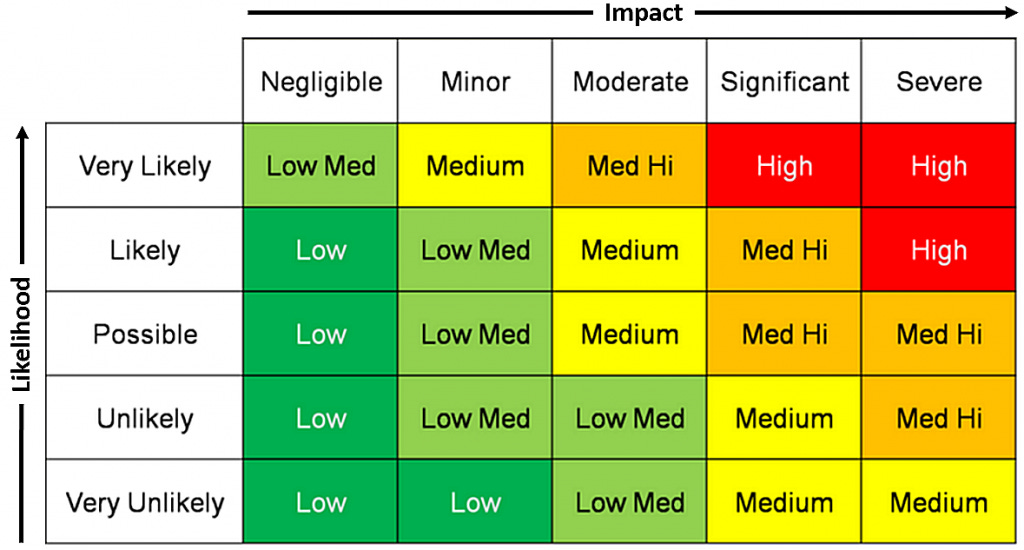

A risk assessment was produced for key workshop processes including routing, drilling, table saw, and mitre saw operations. Hazards included entanglement, tool jamming/binding, dust/splinters, electric shock, burns from hot drill bits, and trips from cords across walkways.

The build was documented over the semester with dated progress entries. Key milestones included:

Evaluation was completed against the original criteria. Strength was tested through real use: the bench was used with multiple tools and even used as the surface for assembling parts of the bench itself.

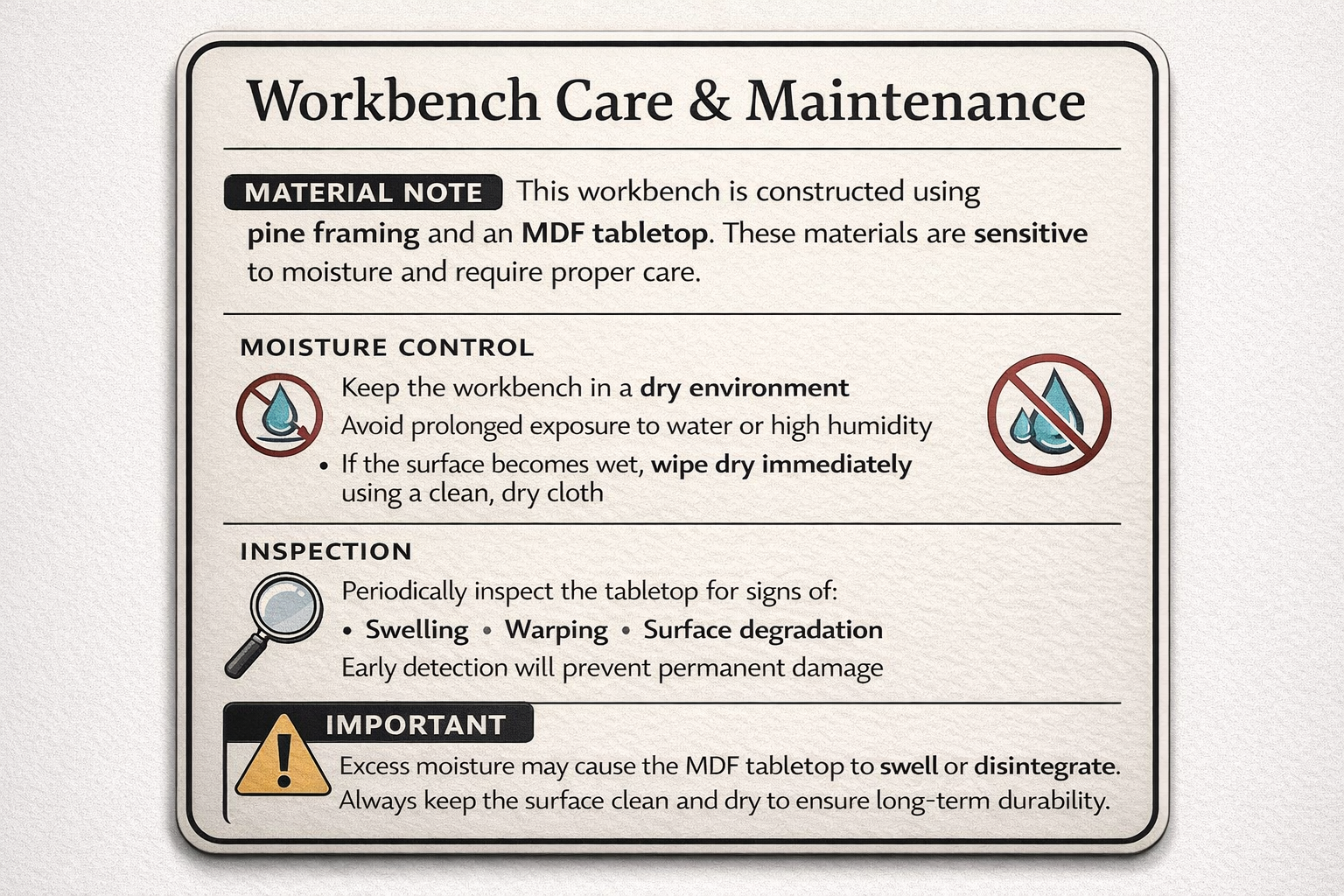

A care label was produced to support long-term durability:

This project demonstrates a complete product design workflow: user profiling → constraints/specs → concept evaluation → production planning → safe fabrication → and criteria-based validation. The final bench delivered the core goals: a strong work surface, organised storage, and maintainable wear components designed for long-term workshop use.