Bavreet Ubhi: Propulsion Engineer

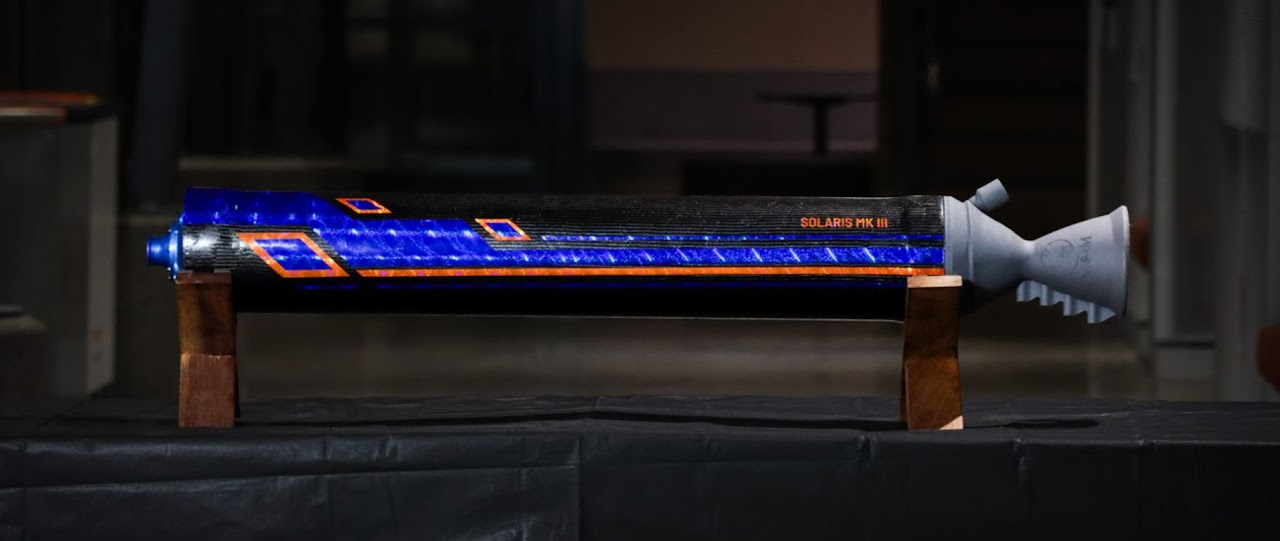

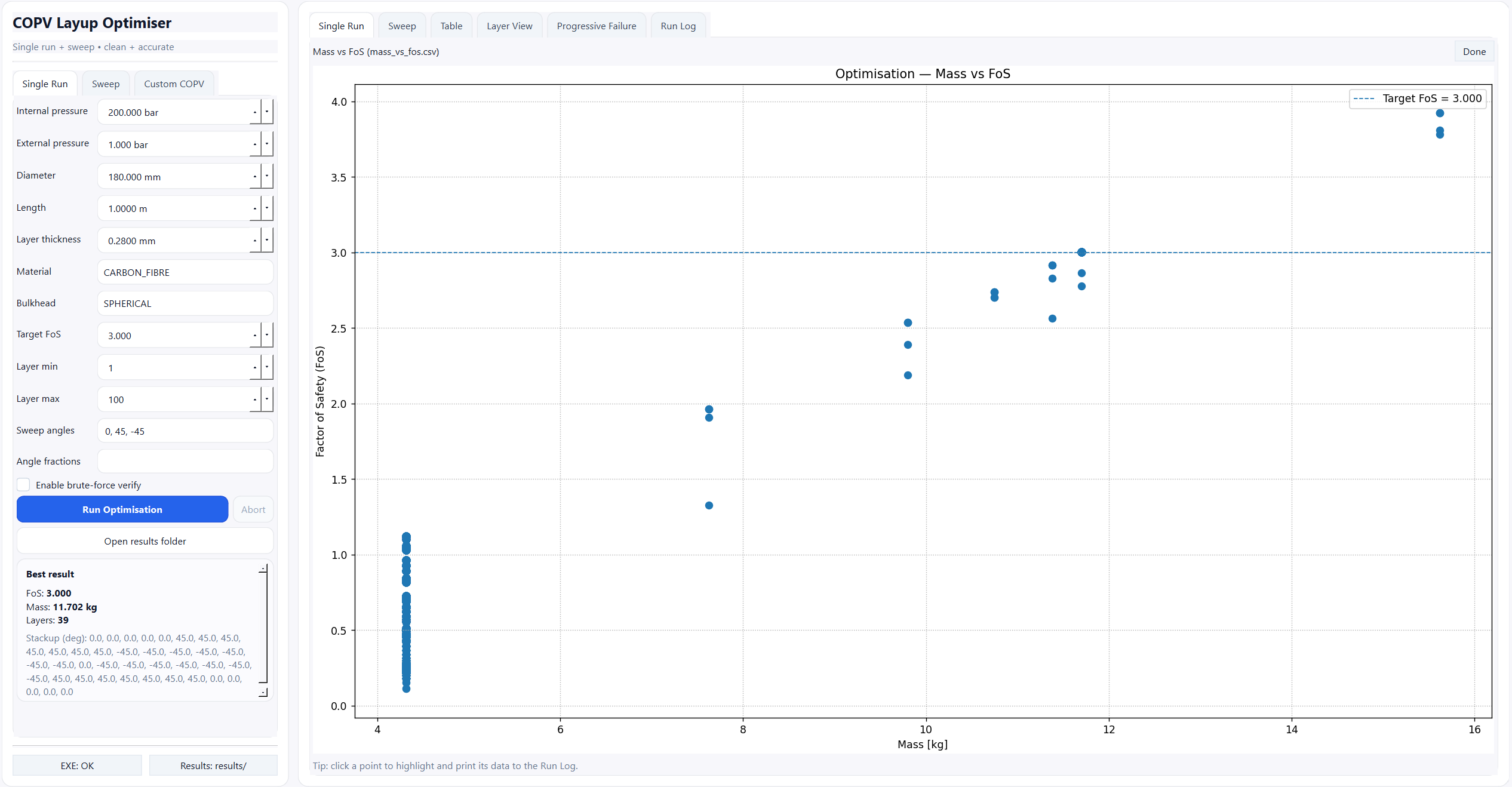

Engineering student driven by a passion for turning complex ideas into functional, high-performance aerospace systems. I specialise in propulsion and composite structures, with experience that spans the entire engineering lifecycle—from early-stage concept modelling and materials research to fabrication, integration, and full-scale testing. My work focuses on delivering designs that balance performance, reliability, and manufacturability, particularly within the demanding context of high-pressure hybrid rocket engines.

Design and Development Tools

Proficient in Fusion 360, Creo Parametric, and Ansys. Skilled in Python and MATLAB for analysis and simulation.

Manufacturing & Testing

Hands-on experience with manual/CNC machining, composite layups, and hybrid engines. Confident in fast-paced, safety-critical environments.